Search Results:

In the production facility of Arcola, a leading diversified manufacturing service provider in the UK, the efficiency and quality are constant pursuit. As an integrated operation combining signage fabrication, manufacturing, and large-format printing under one roof, Arcola is constantly seeking solutions to enhance the production capability and quality of its extensive product line. It was this demand that drove the JWEI Flatbed Cutter to become a pivotal part of their production line.

From Demonstration to Confidence: Cutting Quality Beyond Expectations

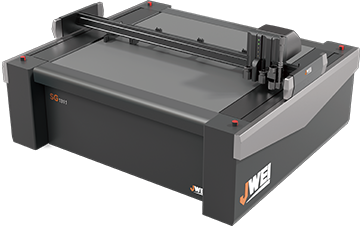

When it was time to upgrade their equipment, Chris Payne, Commercial Sales Director of Arcola, and his team evaluated various options. Despite having used other brands previously, the live demonstration of the JWEI Flatbed Cutter proved decisive. The team was not only impressed by the machine's wide array of tool configurations but also discovered, upon closer inspection, that its cutting results and finished product quality far exceeded their expectations. This visually superior and structurally more robust performance made Arcola realize that the JWEI Flatbed Cutter could provide solid quality assurance for their diverse range of products they deliver to their customers.

Seamless Integration into Existing Workflow, Unlocking New Wide-Format Markets

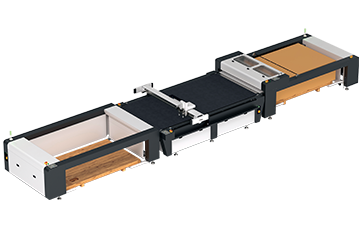

Arcola's production ecosystem was already highly integrated. They had previously been impressed by the ease of use and output quality of the Mimaki flatbed printer and its LUS 120 inks. Choosing the JWEI Flatbed Cutter was partly due to its ability to work in synergy with their existing setup. When they later introduced a 3.2-meter-wide roll-to-roll printer, the consistency of the ink system ensured color and quality stability throughout the entire workflow from printing to cutting. This combination not only significantly boosted their production capacity but also opened up entirely new market opportunities that required wide-format output.

A Truly Versatile Core: From Daily Production to Flexible Support

When Arcola's previous cutting table neared the end of its service life, the JWEI Flatbed Cutter stood out with its highly competitive price point and unparalleled tool variety. Today, it operates at full capacity daily, efficiently processing everyday materials like corrugated plastic, foam board, and ACM, becoming an indispensable pillar of their production workflow.

However, the value of the JWEI Flatbed Cutter extends far beyond this. Its true strength lies in the flexibility it brings to production. Whenever the workshop’s laser cutter or CNC machines face scheduling gaps, the JWEI Flatbed Cutter can quickly switch roles, effortlessly handling more challenging materials such as hardwood and acrylic. This "multi-function in one machine" characteristic makes it a truly versatile platform for Arcola to handle complex orders and optimize overall equipment utilization.

Collaborating with Expert Partners to Shape Success

Arcola has maintained a long-standing, solid partnership with CMYUK, JWEI's UK partner. CMYUK's comprehensive expertise across roll-fed and flatbed equipment, coupled with their commitment to deeply understanding customer needs and providing integrated solutions, has strongly supported the successful implementation of the JWEI Flatbed Cutter at Arcola. This close partnership ensures that technical advantages are accurately translated into tangible productivity and market competitiveness for the customer.

In Arcola's story, the JWEI Flatbed Cutter is more than just a cutting machine; it is a core piece of equipment enabling manufacturing diversification, enhanced quality consistency, and flexible adaptation to market changes.