Search Results:

Products

News & Insights

Go Back

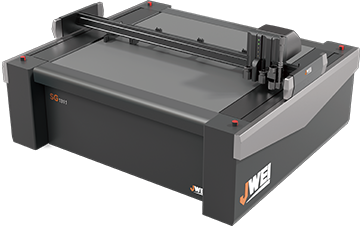

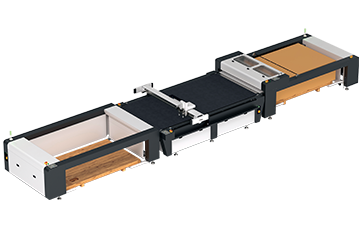

Sheets Auto Loading-unloading System Intelligent Integrated Cutting Solution

Auto loading-unloading intelligent integrated Cutting Solution,compatible with a wide range of materials, can cut a variety of KT board ,honeycome board etc.Ideal for “light production” fully automated assembly line operations.

| Your Needs | JWEI Solutions |

| The number of small-batch personalized orders is increasing, creating a gap in cutting efficiency. | Ideal for “light production” fully automated assembly line operations. |

| Enables unattended operation with fully automated loading and unloading. | Automatic feeding and collecting system; rapid loading with material shortage detection. |

| Front-side QR code scanning is ineffective, and automatic flipping is not possible. | With the back-scanning function enabled, issues such as slotting, overcutting, and creasing are effectively resolved. |

| Multiple processes need to be executed simultaneously, but tool changes are time-consuming and labor-intensive. | The automatic tool-changing function completely eliminates the time wasted on manual bit replacement. |

| Batch loading and unloading is cumbersome; it's essential to minimize handling steps as much as possible. | Forklift pallet loading and unloading ensures fast material flow before and after cutting. |

| Stable and reliable cutting equipment eliminates losses caused by equipment-related issues. | Provides 30 years of trusted reputation, with self-developed control systems ensuring safety and stability, and full lifecycle service. |

Technological process of advertising industry

Order Taking

Customer places order / Place orders on behalf of customers

Layout

JWEI Software

Automated plate imposition and layout, distribution and printing.

Printing

Compatible with most mainstream printers currently available on the market.

Processing

Laminating,Overlaying

Cutting

File recognition;QR Positioning;

Projection-based segmentation — customer info at a glance;

High-speed precision cutting

Packaging

Visualized operation, preventing customer information errors.

Material status identification via container color coding.