Search Results:

Products

News & Insights

Go Back

Intelligent Cutting Solutions for High-End Fashion Customization

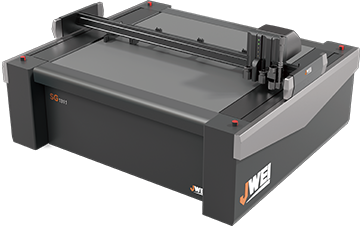

JWEI’s projection-based stripe and check alignment system easily handles cutting for suits with aligned patterns, achieving an average production efficiency of 12 minutes per set.

| Your Needs | JWEI Solutions |

| Custom suit manufacturing requires integration with the MES system for fast turnaround time management. | JWEI software supports integration with mainstream MES systems, facilitating rapid transfer of cutting files and generation of cutting reports. |

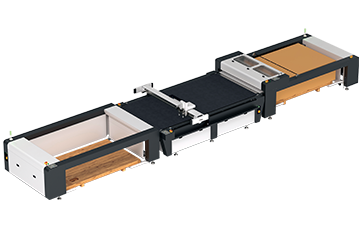

| Some high-demand customizations require secondary precision cutting of the cut pieces; for example, the front piece also needs secondary precision cutting after the chest lining is applied. Manual operation is inefficient and lacks cutting accuracy. | JWEI software combined with high-definition projectors and various types of cutting tools easily handles secondary precision cutting and fine adjustments for suits. |

| Custom suits and shirts often require precise alignment of stripes and checks. Manual cutting is inefficient, results in high material waste, heavily depends on skilled craftsmen, and leads to high management costs. |

Solution 1: JWEI’s projection-based stripe and check alignment system easily handles cutting for suits with aligned patterns, achieving an average production efficiency of 12 minutes per set. Solution 2: JWEI’s vision-based stripe and check alignment system easily handles cutting for shirts with aligned patterns, achieving an average production efficiency of 4 minutes per set. |

| Custom orders have tight delivery deadlines, with limited time for each process step. Cutting especially requires quick response, thus imposing higher demands on cutting speed for the equipment. | The contour cutting tool has a maximum cutting speed of 1500 mm/s, and the notch cutting tool operates at a maximum frequency of 2 times per second. Folding and cutting a full XL-sized suit set takes only 3 minutes. |