Search Results:

Products

News & Insights

Go Back

Flexo cutting production solutions

JWEI cutting machines are equipped with specialized flexo plate slotting tools, enabling fast and precise slotting and chamfering, thereby enhancing the overall quality of flexo plates.

| Your Needs | JWEI Solutions |

| Flexo plate comes in a wide variety of types, and the flexo plate are complex and difficult to cut. | Fast cutting and rapid sorting and collecting of materials significantly boost work efficiency. |

| Manual processing cannot achieve precise slotting and chamfering of flexo plates, often leading to issues such as plate mounting errors and ink scraping during printing. | JWEI cutting machines are equipped with specialized flexo plate slotting tools, enabling fast and precise slotting and chamfering, thereby enhancing the overall quality of flexo plates. |

| Manual cutting results in large dimensional deviations, leading to significant positioning errors during flexo plate mounting. | CCD camera precision: Ensures accurate positioning and cutting, eliminating dimensional errors. |

| From plate making to cutting, the workflow is often complicated and disorganized, resulting in low efficiency and a high risk of errors. | The powerful collaboration between JWEI and ESKO streamlines the entire flexo workflow — from design to imposition, plate making, and cutting — making the process simpler and more efficient. |

| Ultimate cost control to ensure a balance between profitability and product quality. | A single operator can manage multiple machines simultaneously. With integrated layout and imposition functions, this setup delivers significant cost optimization results. |

| Stable and reliable cutting equipment to eliminate losses caused by machinery | Backed by 30 years of proven reputation, featuring self-developed control systems for safety and stability, and full lifecycle service support. |

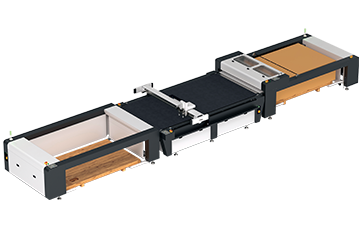

Complete Production Workflow

Order Receiving

Prepress automated production

Autoscreen film

Supports connection with most mainstream printing machine on the market

Automatic label layout

Plate-making

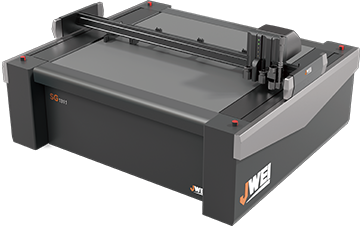

File recognition; QR Positioning; Zoned vacuum suction; High-speed precision cutting

Cut and slice

File recognition

OR Positioning

Zoned vacuum suction

High-speed precision cutting