Search Results:

Watch Video

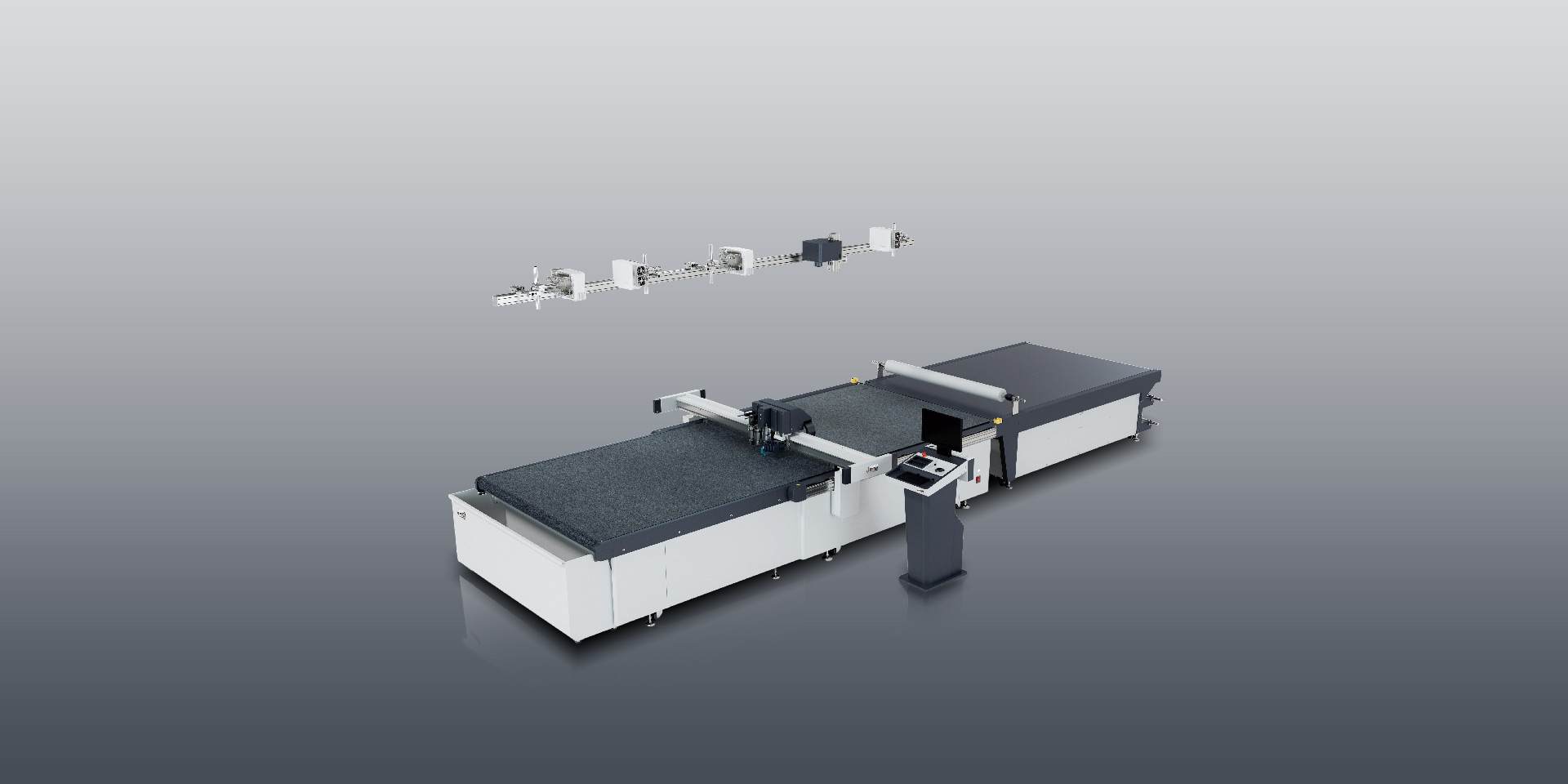

Independent punching module enables high-speed punching of straight notches and V-notches, while the rotary punch/needle punch supports functions such as darting, pocket positioning, and more. It can perform advanced cutting processes, including external V-notch cutting, internal corner cutting without overcutting, and precise cuts with a minimum 2mm gap without overcutting.

The four-cartridge inkjet module delivers double the efficiency compared to commonly used dual-nozzle systems on the market. It produces clear and precise ink lines, with a cutting-to-print alignment error controlled within 1mm. The line thickness is adjustable, and extended cutting files can be processed continuously across multiple sections.

Equipped with a brand-new control system, the machine achieves higher arc-turning speeds and allows tool rotation during movement. Combined with a high-performance, high-power servo motor, it delivers faster cutting speeds and significantly improved overall efficiency.

The newly upgraded vacuum system ensures stronger material hold and fixation, resulting in improved cutting quality for small angles, small pieces, and flexible materials.

Unlike traditional methods requiring perfectly aligned placement of patterned fabrics, simply lay the fabric flat. The vision system automatically matches the pattern with the CAD layout, enabling precise cutting of stripe- and plaid-matched pieces.

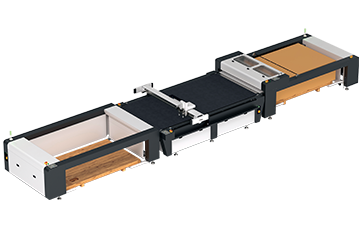

Waste clearance activates automatically during table rolling, enabling fast and convenient cleaning of the working surface.

The automatic waste removal function activates as the cutting table rolls, enabling fast and convenient cleanup of the work surface.

Part description

Part description

Part description

Part description

Part description

JWEI reserves the right of final interpretation of the following parameters, subject to change without prior notice.

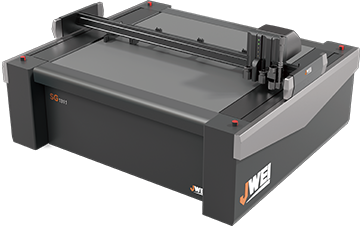

| Model | TB05-2218-RQ |

| TB05-2218-RQ | Tool heads are easily interchangeable, with functions for cutting, notching, and positioning needles. It also features various module kits for hole punching and inkjet printing for both text and patterns. |

| Tools | Rotary Tool, Oscillating Tool, Cutting Tool, Positioning Tool, I/V Notching Tool, Rotary Punch Needle/Punching Tool, Plotting Tool |

| Maximum cutting speed | 1500mm/s |

| Cut material | Knit Fabrics, Woven Fabrics, Fur and Leather (e.g. Sheepskin), Oxford Cloth, Canvas, Foam, PU/PVC Leather, Cotton-Linen, Blends, Blended Fabrics,Bagging Fabrics, Upholstery Fabrics, Carpet Textiles |

| Material Fixation Mode | Vacuum suction |

| Repeat Precision | ±0.1mm |

| Network transmission distance | Ethernet port |

| Residue cleaning system (Optional) | Residue cleaning system waste automatic collector |

| Stripe and Plaid Matching System(Optional) | Vision Stripe and Plaid Matching System |

| Interface | LCD touch screen with EN&CN languages |

| Drive System | High-Precision Motor, Linear Guide Rails, Rack and Pinion |

| Rated Power | 13kW |

| Data Format | PLT, HPGL, NC, AAMA, DXF, XML, CUT, PDF |

| Rated Voltage | Rated Voltage |

| Effective Cutting Area | Effective Cutting Area |

| Material Receiving Area | 2000mm×1800mm |

| Machine Size | 5005mm×2937mm×1350mm(Excluding Material Receiving Hopper and Operating Table) |

Note: * will be determined based on the specific materials in the actual application scenario.