Search Results:

Watch Video

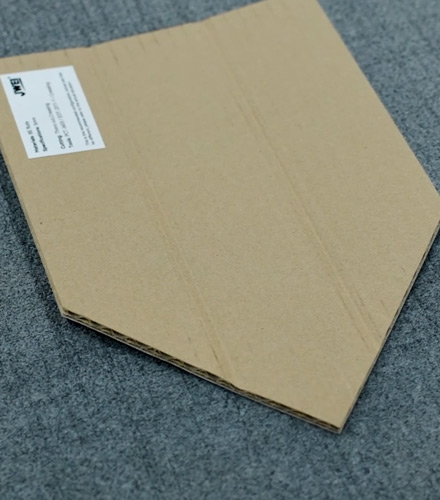

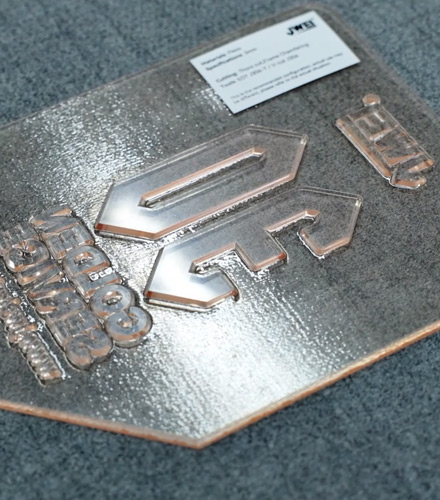

Equipped with a high-frequency Maxon motor, reaching speeds up to 18,000 RPM, and featuring specially made tungsten steel hardened blades, it easily handles cutting various harder and thicker materials (such as corrugated cardboard, honeycomb cardboard, KT board, and foam board) with fast speed and smooth, neat edges.

Capable of handling materials with a thickness of up to 5mm. Compared to the oscillating tool, it cuts at a faster speed.

Four sets of creasing wheels with different widths are available, allowing for perfect creasing on various corrugated cardboard and cardstock; optional PVC creasing wheels are available for PVC creasing.

Data transmission is flexible and stable, with enhanced automation scalability; it supports remote upgrades and maintenance, as well as machine control and file access within a local area network (LAN).

The safety collision design is simple and elegant, featuring an internal infrared light grid device that is highly responsive, ensuring the personal safety of operators and the secure operation of the machine.

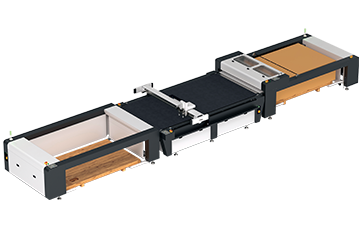

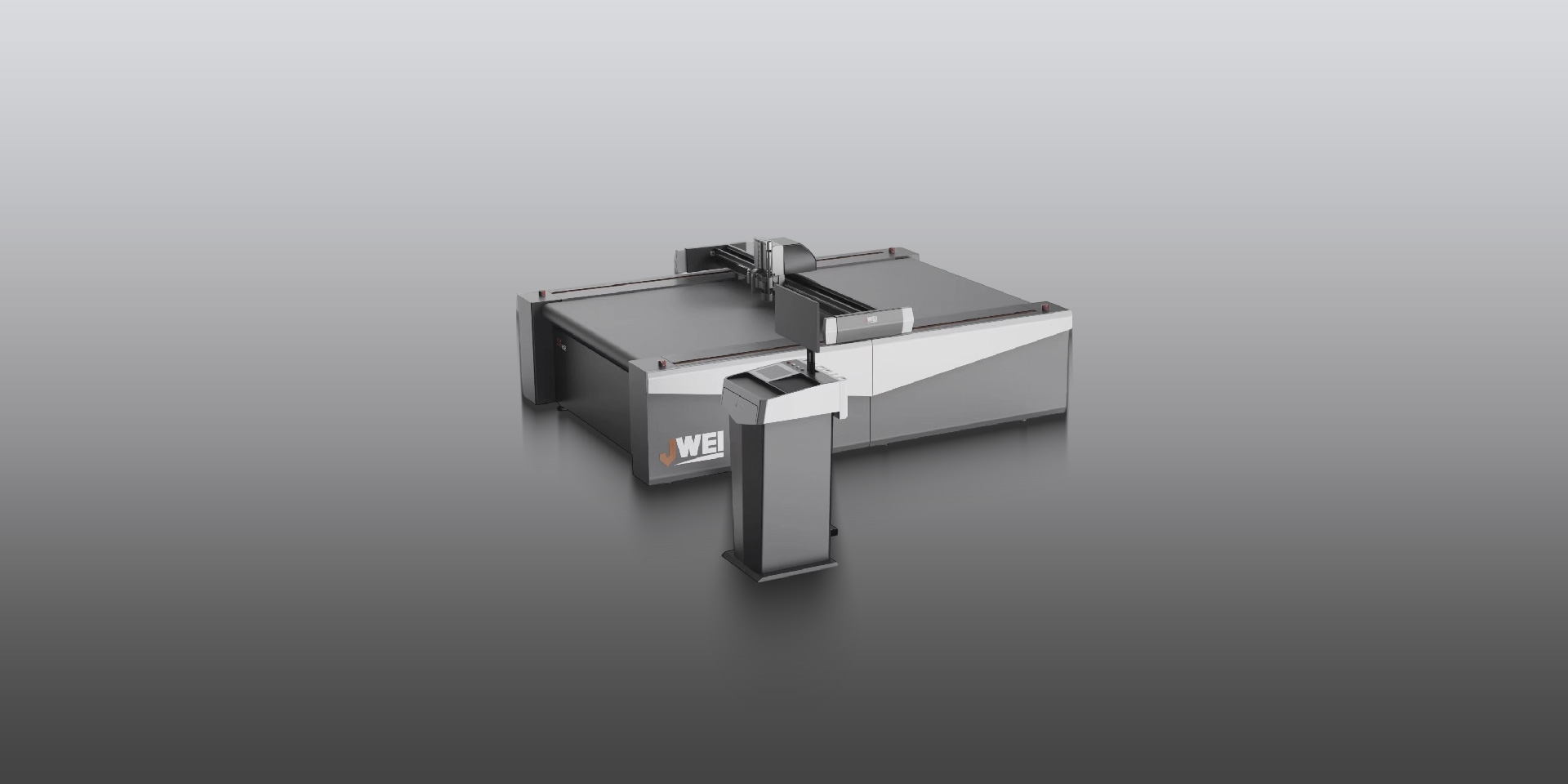

Made with aerospace-grade aluminum honeycomb panels: strong, weather-resistant, highly flat, and resistant to deformation even under heavy loads. The internal honeycomb structure allows smooth airflow. Optional zoned vacuum suction provides powerful airflow and strong suction force.

This platform integrates an emergency stop button with a touch screen human-machine interface, which is user-friendly and easy to operate, facilitating the quick setup of various cutting parameters. It also provides space for PC installation.

For printed materials, the camera positioning system enables fast and accurate cutting alignment. With the integrated QR code-based job classification module, it supports automated image adjustment and production of different batches in small quantities.

Part description

Part description

Part description

Part description

Part description

Part description

Part description

JWEI reserves the right of final interpretation of the following parameters, subject to change without prior notice.

| Parametera | Description | |

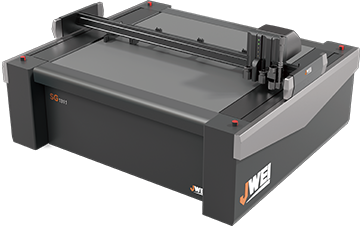

| Model | SG1625 | |

| Multi-functional Tool Head | 2 Tool heads | 3 Tool heads |

| Tools | Multi-functional Tool Head Multi-tool fixing holes, quick insert tool fixing, easy-to-replace cutting tools, plug-and-play, set cutting, creasing, drawing, router and other functions in one, optional ATC module | |

| Tools | Electric oscillating tool, drag knife, rotary tool, router tool module, plotting tools, etc. | |

| Fastest speed | 2000mm/s * | |

| Max. Cutting Thickness | 50mm * | |

| Repeat Precision | <0.05mm * | |

| Cutting Materials | ABS board, PVC board, space board, aluminium-plastic board, lamp sheet, back glue, PVC foam board, KT board, acrylic, magnetic sticker, self-adhesive,Cardboard, corrugated, greyboard, PVC/PET, EPE/EVA, hollow sheet, honeycomb panel, flexo, etc. | |

| Material Fixation Mode | Vacuum absorption | |

| Software resolution | 0.025、0.01、0.1 optional | |

| Transmission Mode | Ethernet port | |

| Drive System | Bus controller, advanced servo system, imported linear guide rail, lead screws, grinding level 0 backlash helical teeth | |

| Instruction system | HP-GL compatible format | |

| Machine Power | 12kW | 14kW |

| Rated Voltage | 380V±10% | |

| Effective Cutting Size (WxL) | 1600mm×2500mm | 1600mm×1200mm |

| Machine Size (WxLxH) | 2570mm×3380mm×1415mm | 2570mm×2080mm×1415mm |

Note: * will be determined based on the specific materials in the actual application scenario.