Search Results:

Watch Video

wide material compatibility

Unlike traditional methods that require aligning the fabric stripes and checks perfectly horizontal and vertical, this system only needs the fabric to be laid flat. With the visual stripe and check matching system, it directly matches the warp and weft CAD layout to cut the required pattern pieces with aligned stripes and checks—making the process simple, efficient, and fast.

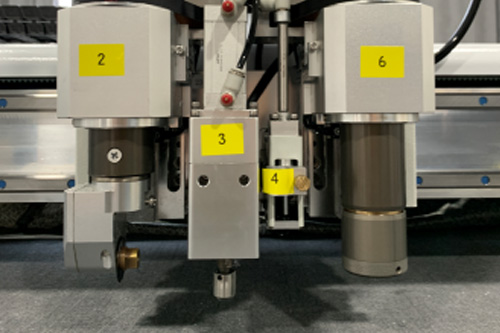

This configuration combination is primarily designed for standard primary cutting operations. It is well-suited for high-speed cutting of fabrics up to 5mm thick using a rotary cutting tool. The I/V notching tool and Rotary punch needle/ punching tool are used for tasks like dart marking and pocket positioning. It supports cutting processes such as external V-notching, prevents over cutting on internal corners, and enables cutting with minimum clearances as small as 2mm without over cutting.

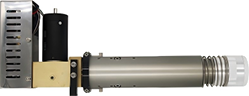

It eliminates traditional threaded tool locking. The system comes standard with the latest quick-change tool locking design, allowing one-press rapid tool installation and removal. This greatly improves ease of operation and production efficiency, while eliminating the common issue of automatic loosening associated with threaded locking mechanisms.

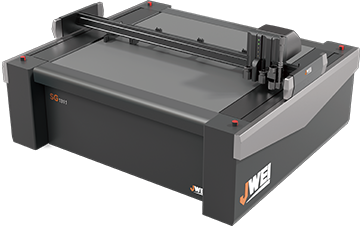

The machine base utilizes high-quality 4mm thick profiles treated with a high-temperature spray coating process. This construction increases overall weight, minimizes deformation from environmental or climatic factors, and ensures long-term stability without performance degradation over time. Compared to conventional painting, this high-temperature spray coating is more environmentally friendly and offers superior color retention.

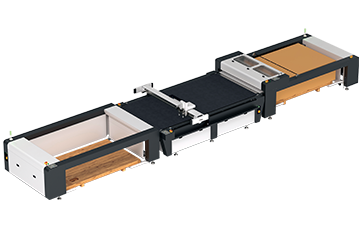

Waste clearance activates automatically as the table moves, enabling fast and convenient cleaning of the working surface.

Features a standard 2.5-meter receiving platform that enables simultaneous cutting and sample collection. This design boosts overall production efficiency by up to 50% compared to models limited to cutting-only zones.

Designed for noise-sensitive environments (e.g., densely populated areas, office buildings, sample garment workshops). Operating noise remains below 70 decibels (dB) under standard conditions, producing a low-pitched, non-piercing sound profile.

Part description

Part description

Part description

Part description

Part description

JWEI reserves the right of final interpretation of the following parameters, subject to change without prior notice.

|

Model |

CB03Ⅱ-2516-RQ | CB03Ⅱ-2518-RQ | CB03Ⅱ-3016-RQ |

| Multi-functional Tool Head | Easy to replace different tool heads, with cutting, notching, positioning needle functions | ||

| Tool | Rotary tool, I/V notching tool, plotting tool, optional oscillating tool,(circle)drilling tool,drag knife. | ||

| Maximum cutting speed | 1500mm/s | ||

| Maximum cutting thickness | Standard 5mm, with option to increase to 10mm | ||

| Cut material | Knitted, woven, fur (such as sheep shear) Oxford cloth, canvas, sponge, imitation leather, cotton and linen, blended fabrics and other clothing, bags,sofa fabrics and carpet fabrics etc. | ||

| Material Fixation Mode | Vacuum suction | ||

| Repeat Precision | ±0.1mm | ||

| Network transmission distance | ≤350m | ||

| Data Transmission Mode | Ethernet port | ||

| Plaid/stripe matching pattern | Visual plaid/stripe matching system | Visual plaid/stripe matching system | Visual plaid/stripe matching system,Projection plaid/stripe matching system |

| Interface | Touch screen with En&CN languages | ||

| Drive System | High precision motor, linear guide rail, synchronous belt | ||

| Rated Power | 10kW | ||

| Data Format | PLT、HPGL、NC、AAMA、DXF、XML、CUT、PDF、GB、BOK | ||

| Rated Voltage | AC 380V±10% | ||

| Total Weight | 1095kg | 1335kg | 1250kg |

| Effective Cutting Size | 2500mm×1600mm | 2500mm×1800mm | 3000mm×1600mm |

| Visual Working Area | 2300mm×1600mm | 2300mm×1800mm | 2500mm×1600mm |

| Machine Size | 6068mm×2504mm×1325mm | 6068mm×2704mm×1325mm | 6770mm×2504mm×1325mm |

Note: * will be determined based on the specific materials in the actual application scenario