Search Results:

Watch Video

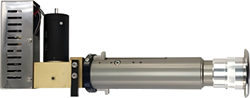

It eliminates traditional threaded tool locking. The system comes standard with the latest quick-change tool locking design, allowing one-press rapid tool installation and removal. This greatly improves ease of operation and production efficiency, while eliminating the common issue of automatic loosening associated with threaded locking mechanisms.

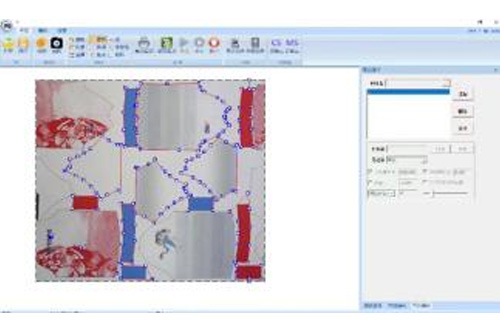

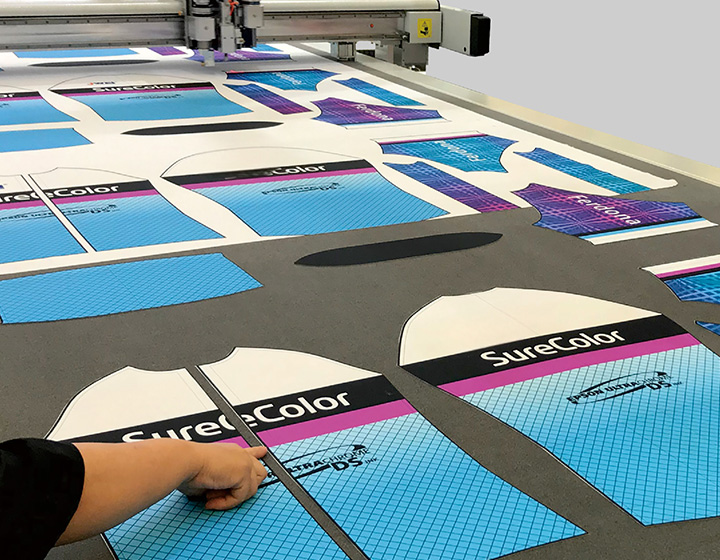

JWEI’s proprietary CAD software suite integrates vision recognition and cutting modules. It features automatic contour detection, image nesting, layout optimization, and built-in drawing tools to generate cutting templates. This solution effectively addresses the challenges of complex material cutting and simplifies high-difficulty fabric placement.

Featuring sleek anti-collision design with built-in infrared light curtains for instantaneous response. This comprehensive safeguarding solution protects both operators and machine integrity during high-speed operations.

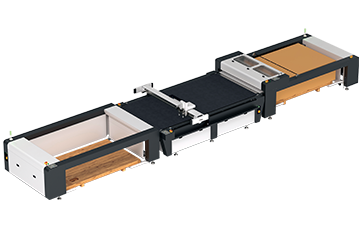

Industry-first aerospace-grade aluminum honeycomb platform delivers exceptional durability, weather resistance, and surface flatness. Maintains dimensional stability under heavy loads while its cellular structure enables smooth airflow. Optional zoned suction with ultra-powerful vacuum.

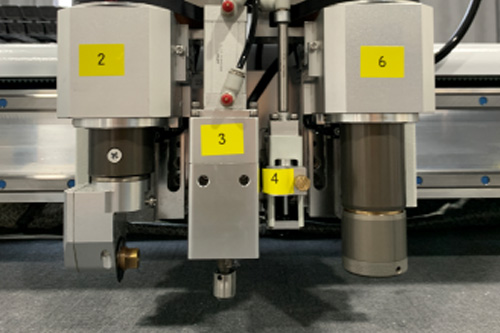

The combination of oscillating knife tool + 1mm oscillating knife tool + rotary punch/pin is ideal for applications requiring precise notch cutting with the 1mm vibration tool. The oscillating knife enables high-speed cutting of single-layer printed textiles, while the 1mm vibration tool can also be used independently for high-speed cutting of printed leather and other materials that are not suitable for oscillating knife cutting.

Part description

Part description

Part description

Part description

Part description

JWEI reserves the right of final interpretation of the following parameters, subject to change without prior notice.

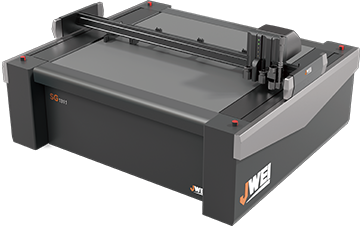

| Model |

CB03Ⅱ-2516-RQ |

| Multi-functional Tool Head | Easy to change different tool heads, with cutting, positioning needle function |

| Tool | Active round tool, plotting tool, optional oscillating tool, round punching tool |

| Maximum cutting speed | 1500mm/s |

| Maximum cutting thickness | Standard 5mm, additional 10mm available upon request. |

| Cut material | Knitted, woven, fur (such as sheep shear) Oxford cloth, canvas, sponge, imitation leather, cotton and linen, blended fabrics and other clothing, sofa fabrics and carpet fabrics etc. |

| Material Fixation Mode | Vacuum suction |

| Repeat Precision | ±0.05mm |

| Network transmission distance | ≤350m |

| Data Transmission Mode | Ethernet port |

| Interface | Touch screen with En&CN languages |

| Drive System | High precision motor, linear guide rail, synchronous belt |

| Rated Power | 10kW |

| Data Format | PLT、HPGL、NC、AAMA、 DXF、XML、PDF |

| Rated Voltage | AC 380V±10% |

| Total Weight | 910kg |

| Effective Cutting Size | 2500mm×1600mm |

| Visual Working Area | 2300mm×1600mm |

| Machine Size | 3571mm×2504mm×1325mm |

Note: * will be determined based on the specific materials in the actual application scenario.