Search Results:

Products

News & Insights

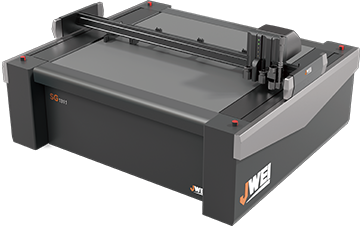

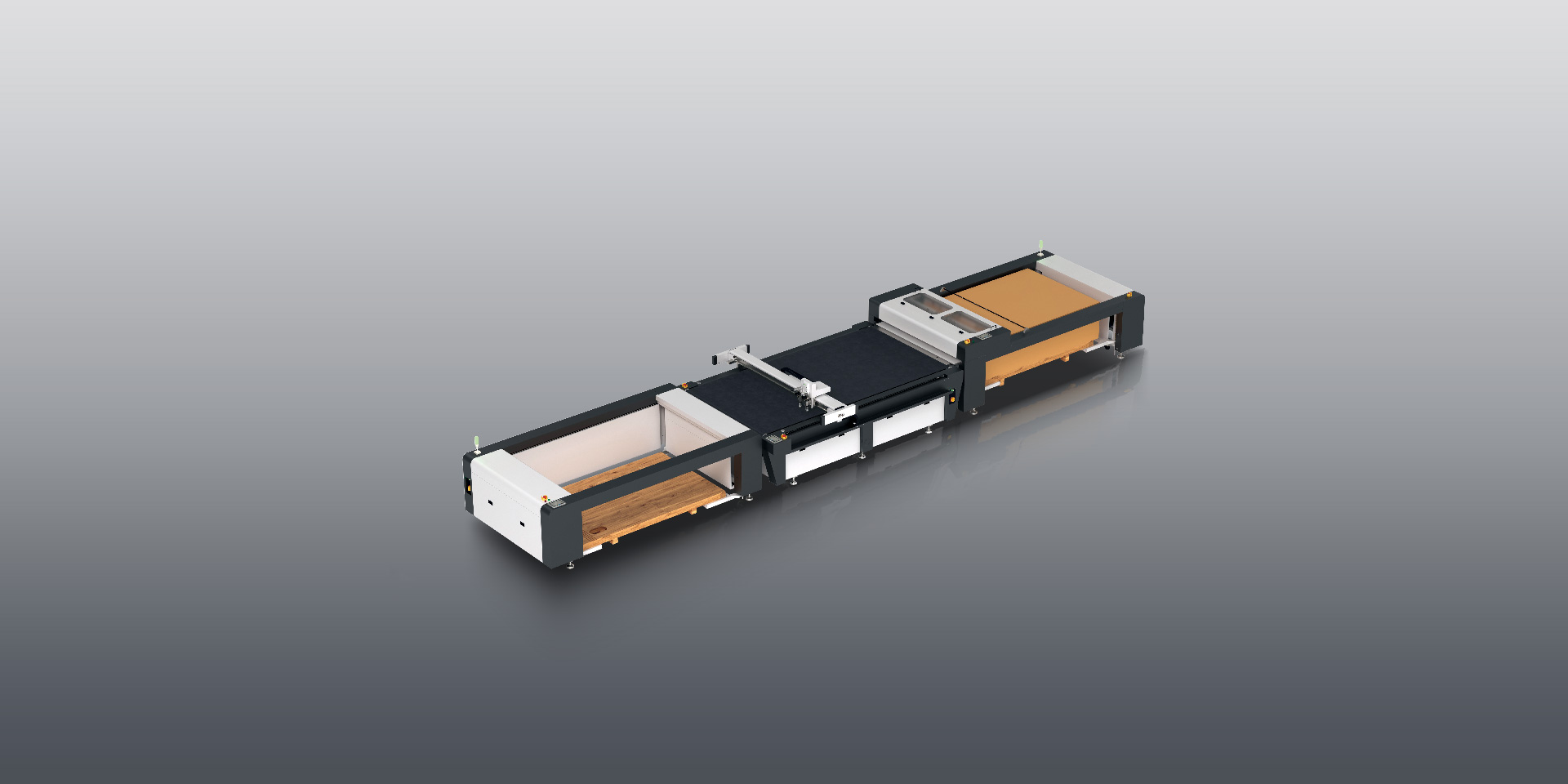

CB03Ⅱ-2516-RM

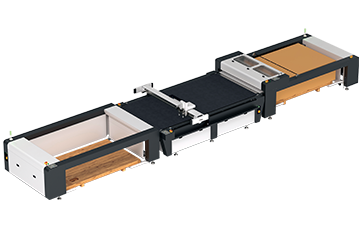

Auto Loading-unloading System

Watch Video

Handle batch processing of various materials

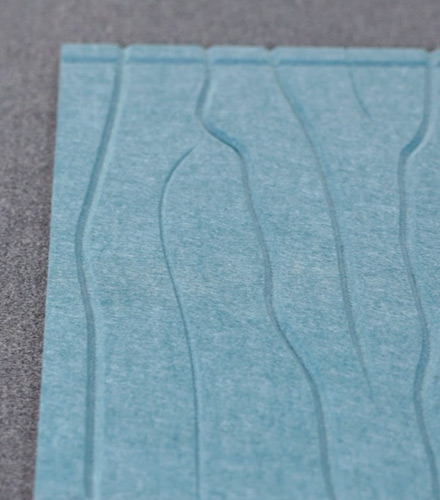

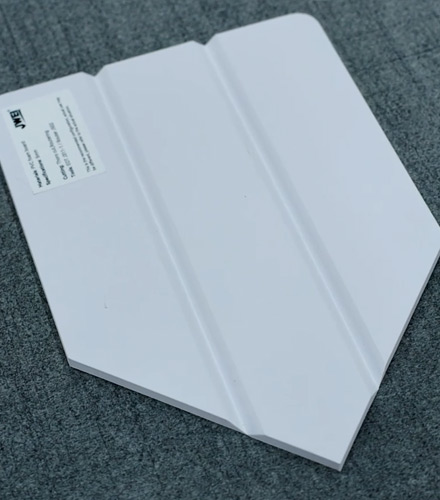

Achieve production process more efficient and optimum cut quality, JWEI CB03II-2516-RM fully automation digital cutting tables increases its market share and impresses manufacturers by the new technical capabilities which has massively helped with their production output, CB03II-2516-RM digital cutting tables specialize in handling creative packaging products ,advertising products and Sound-absorbing products made from polyester fiber board,corrugated cardboard, coated paper, PVC, special paper, grey board, honeycomb board, ABS board, PVC sheet, EPE, EVA foam and other materials.

Application Scenarios

CB03II-2516-RM digital cutting tables with loading unloading,for small batch production line intelligent integrated cutting solution, compatible with a wide range of materials, can cut a variety of cardboard,such as Corrugated paper, grey board, honeycomb board, EPE, EVA foam, PVC board, KT board, etc.

Optional Tools

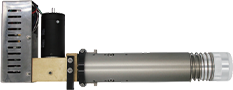

Electric oscillating Tool

Part description

Universal Cutting Tool

Part description

Creasing Wheel Tool

Part description

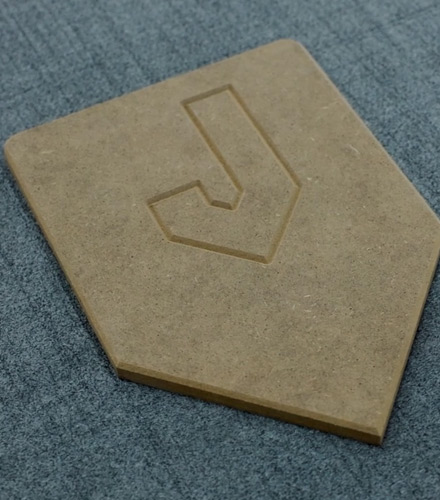

V-CUT Tool For Grey Board

Part description

V-CUT Tool For Photo Frame

Part description

V-CUT Tool For Multi-angle

Part description

V-CUT Tool For Photo Frame

Part description

Electric Foam Cutting Tool

Part description

Explosion-proof Pressure Wheel

Part description

Technical Parameters

JWEI reserves the right of final interpretation of the following parameters, subject to change without prior notice.

|

Model |

CB03 Ⅱ -2516-RM auto Loading-unloading System |

| Multi-functional Tool Head | Double tool fixing holes, tool quick-insert fixation way, easy to change cutting tools, plug and play. Gather cutting, creasing,drawing functions in one. |

| Tools | Electric oscillating tool, drag knife tool, plotting tools |

| The Max Cutting Speed | 1500mm/s (Depends on different kinds of materials) |

| The max cutting thickness | 50mm (Depends on different kinds of materials) |

| Repeat precision | ±0.05mm |

| Material | Corrugated paper, grey board, honeycomb board, EPE, EVA foam, PVC board, KT board, etc |

| Material Fixation Mode | Vacuum suction |

| Transmission port | Ethernet port |

| Drive System | High-end digital servomotor, imported linear guide, synchronous belt, lead screw |

| Rated Power | 17kW |

| Rated Voltage | 380V±10% |

| Maximum loading height (including pallets’ height) | 750mm |

| Maximum feeding thickness | 30mm |

| Single sheet feeding weight | 5kg |

| Maximum loading-unloading material size | 2500mm×1600mm |

| Minimum loading-unloading material size | 900mm×600mm |

| Effective Cutting Size | 2500mm×1600mm |

| Machine Size | 10660mm×2620mm×1325mm(feeding:3630mm×2060mm×1250mm、cutting3571mm×2504mm×1325mm、receiving:3630mm×2060mm×1250mm) |

Note: * will be determined based on the specific materials in the actual application scenario.