Search Results:

Products

News & Insights

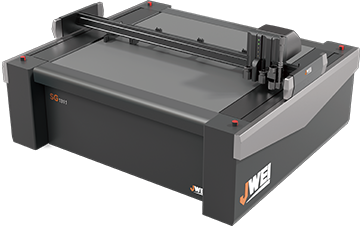

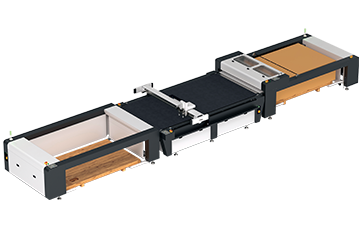

Optimizing Corrugated Cardboard Cutting with JWEI Flatbed Digital Cutter

In today’s manufacturing landscape, the precision and efficiency of cutting processes are crucial, especially when dealing with materials like corrugated cardboard. Whether you're producing packaging, signage, or display graphics, the right cutting equipment can make all the difference. This blog post will guide you through the key considerations for choosing cutting equipment and highlight the advanced solutions offered by JWEI Digital Cutter.

Why Choose Digital Cutting for Corrugated Cardboard?

Digital cutting technology has transformed the way we handle flexible materials, including corrugated cardboard. Here are some key advantages:

- Precision and Accuracy

- Digital cutters use advanced software and hardware to achieve highly accurate cuts, ensuring consistency and reliability in every project.

- Versatility

- These machines can handle a wide range of corrugated cardboard thicknesses and types, making them suitable for various applications from thin packaging to thick display boards.

- Efficiency

- Automated processes reduce setup time and increase productivity, making digital cutters ideal for both small and large-scale projects.

- Cost-Effectiveness

- While the initial investment might be higher, the long-term benefits include reduced material waste, lower labor costs, and increased throughput.

- Environmental Friendliness

- Digital cutting minimizes waste and reduces the need for additional finishing processes, contributing to a more sustainable manufacturing practice.