Search Results:

Products

News & Insights

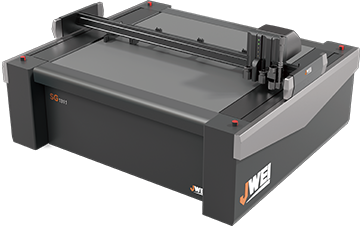

JWEI Composite Material CNC Cutter: Precision Cutting for Advanced Applications

JWEI Composite Material CNC Cutter is an advanced cutting solution designed for a wide range of composite materials used across various industries, including aerospace, automotive, and textiles. This high-precision flatbed cutter excels in processing medium-density non-metal materials such as carbon fiber prepreg, glass wool, rubber gaskets, PU leather, composite sponges, 3M reflective signage, soft PVC, XPE, aramid honeycomb boards, and technical fabrics.

Equipped with a multifunctional tool system and an automated collecting platform, the JWEI Composite Material CNC Cutter streamlines production by optimizing material handling, cutting, and collection for efficient, fully automated performance.

Key Features of the JWEI Composite Material CNC Cutter

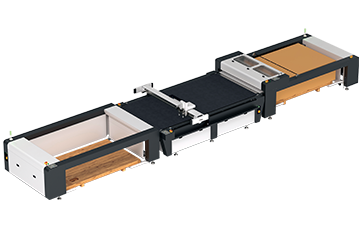

- Automated Roll Feeder

The automated roll feeder is designed for efficiency and precision. Capable of handling two materials simultaneously, it features automatic tension detection and web edge control, ensuring smooth and accurate feeding onto the cutting table. This setup minimizes waste and maximizes productivity by maintaining precise alignment throughout the cutting process. - High-Speed Cutting Platform

The cutting platform is equipped with a sophisticated motion controller and various cutting tools. Interchangeable cutting heads—including rotary, ultrasonic, oscillating, and drag knives—allow for seamless adaptation to different materials, enhancing versatility and cutting quality. Additionally, an integrated marking function enables automatic labeling on materials such as prepregs and glass wool, facilitating easy identification of production details like manufacturing dates and batch numbers. - Automated Collection Platform

The automatic collecting platform efficiently organizes finished products. Utilizing two independent suction modules, the system can handle small and large samples with ease. For smaller items, one module positions the piece precisely; for larger items, both modules work together to ensure accurate placement in designated areas, significantly reducing manual handling.