Search Results:

In the fast-evolving leather goods industry, choosing the right cutting technology is crucial for achieving precision, efficiency, and quality. Traditional cutting methods, such as manual and laser cutting, have limitations that can hinder production quality and output. Flatbed digital cutters, specifically those equipped with oscillating knife technology, offer an advanced solution for leather processing.

Limitations of Traditional Leather Cutting

- Manual Cutting

Manual cutting is labor-intensive and prone to inconsistencies, leading to precision issues and slower production speeds. - Laser Cutting

While laser cutting offers higher precision, it often causes burnt or discolored edges due to the high-temperature process. Additionally, it generates smoke, which is harmful to operators and the environment.

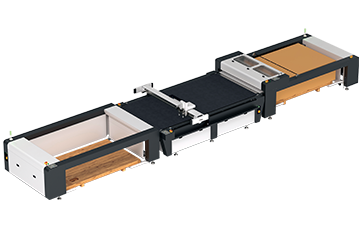

Why Flatbed Digital Cutters Are the Superior Choice

Flatbed digital cutters equipped with oscillating knives overcome the drawbacks of traditional methods, providing the following benefits:

- High Precision: Ensures clean, consistent cuts without errors.

- Edge Quality: Produces smooth, natural edges without discoloration or damage.

- Eco-Friendly: Eliminates smoke and harmful emissions, ensuring a safe working environment.

- Versatility: Adapts to various leather products, including handbags, shoes, clothing, and furniture.

- Efficiency: Increases productivity while maintaining high quality, making it ideal for modern leather manufacturing.

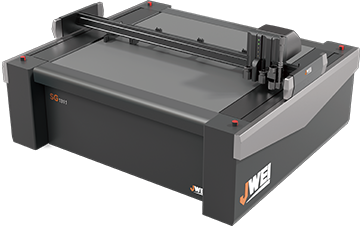

Why Choose JWEI Flatbed Digital Cutters?

With over 30 years of experience, JWEI is a trusted name in the industry. Their flatbed digital cutters are designed for precision and durability, making them an excellent choice for leather cutting. JWEI’s global service network ensures responsive support to meet your production needs.